Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

In industrial piping systems, where high-pressure environments, extreme temperatures, and harsh operational conditions are the norm, maintaining the integrity of the pipes and connections is crucial. One of the key components used to enhance the durability and efficiency of these systems is the Blast Joint. A Blast Joint plays a significant role in ensuring that industrial pipelines function seamlessly under stress, particularly in applications like oil and gas, chemical processing, and power plants.

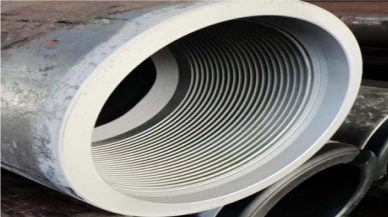

A Blast Joint is a specially designed mechanical joint used in high-pressure and high-stress piping systems to prevent damage caused by the force of explosions, pressure surges, and sudden pressure drops. It is typically installed in systems where sudden changes in pressure, such as those from a gas surge or explosive force, could cause damage to pipes or their connections.

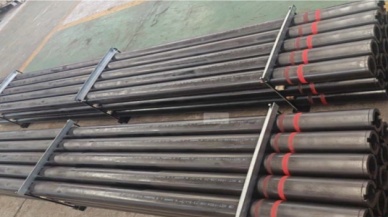

The Blast Joint works as a shock absorber, cushioning and distributing the explosive energy or pressure wave across the piping system, minimizing damage to the pipe and joints. These joints are designed to withstand extreme conditions, ensuring that the integrity of the pipeline is maintained even during high-stress events. They are usually made from high-strength materials such as carbon steel or stainless steel, ensuring both durability and resistance to the harsh chemicals and conditions typically found in industrial environments.

Industrial piping systems are the backbone of many critical sectors, including oil and gas, petrochemical, power generation, water treatment, and more. These systems are responsible for the continuous flow of fluids and gases, often under extreme conditions. Not only do they need to handle the usual demands of transporting liquids and gases, but they also face challenges such as pressure fluctuations, sudden pressure surges, and explosive forces. These fluctuations and forces can cause severe damage to the piping infrastructure, which could lead to system failures, safety hazards, or catastrophic accidents if not properly managed.

To address these challenges, Blast Joints are employed in industrial piping systems. These components play an essential role in ensuring the safe and efficient operation of the system by mitigating the effects of sudden pressure changes, maintaining pipeline integrity, and preventing damage. This article will explore the role of Blast Joints and how they contribute to the performance, safety, and longevity of industrial piping systems.

One of the most significant benefits of Blast Joints is their ability to absorb and mitigate the impact of shockwaves caused by explosive pressure surges. In industries like oil and gas, pipelines are often exposed to high-pressure gas flows. These gas pipelines can experience sudden pressure releases due to various factors, such as changes in valve positions, gas surges, or unexpected disruptions. When there is a rapid release of pressure, a shockwave is generated, which can cause serious damage to the pipeline. In some cases, the impact of such a pressure surge can even lead to pipe rupture or failure.

A Blast Joint acts as a shock absorber in this scenario. It absorbs the brunt of the pressure surge and distributes the shock across the joint, thereby relieving the stress on the rest of the piping system. By doing this, Blast Joints help prevent damage to the pipeline and the associated infrastructure.

Pipelines are exposed to constant stress and pressure during their operation, and sudden pressure fluctuations or explosive forces can significantly compromise their integrity. For example, the force generated by an explosion or pressure surge can cause pipes to bend, rupture, or even break. If this occurs, it can result in hazardous spills, system failures, or even explosions, all of which pose a risk to workers, the environment, and the economy.

This is where Blast Joints come into play. They protect the entire pipeline by absorbing the force generated by pressure surges, preventing the pressure from directly impacting the pipe. By acting as a buffer, Blast Joints ensure that the pipeline remains intact and operational, despite the extreme forces it may face.

In industries like oil and gas, where the stakes are particularly high, the consequences of a pipe failure can be severe. It could result in significant environmental damage, loss of valuable resources, or even loss of life. By preventing catastrophic failures, Blast Joints play an essential role in protecting not only the infrastructure but also the safety of workers and the environment.

The longevity of a pipeline is crucial because pipelines are expensive to install and maintain. With proper care, pipelines can last for many years, but constant wear and tear from pressure fluctuations can shorten their lifespan. Blast Joints contribute to the longevity of industrial piping systems by preventing damage caused by these fluctuations.

By absorbing pressure surges and distributing the force more evenly across the system, Blast Joints reduce the likelihood of fatigue damage, corrosion, and failure. The result is a more durable pipeline that can continue to perform at its optimal level for an extended period.

In many industrial environments, high-stress situations such as emergencies, system startups, or shutdowns can cause sudden pressure spikes. These pressure spikes put immense strain on the entire piping system, which can result in damage if not properly managed. Blast Joints are designed to handle these high-pressure conditions by absorbing the resulting shock and preventing any significant damage.

During system startups, for example, when pressure is rapidly increasing, Blast Joints help stabilize the pressure and prevent damage to the pipeline. Similarly, during shutdowns or emergency events, Blast Joints ensure that the system remains stable despite sudden fluctuations in pressure.

Another key advantage of Blast Joints is their versatility and ease of integration into existing industrial piping systems. Whether you're installing new pipelines or retrofitting old ones, Blast Joints can be seamlessly incorporated into the design without requiring significant modifications. This adaptability is particularly beneficial for facilities that need to upgrade their systems to meet new safety standards or enhance system performance.

The use of Blast Joints is widespread across several industries where pipelines are subject to extreme conditions. Below are some of the primary applications:

In the oil and gas industry, pipelines are often exposed to extreme pressure surges, especially during extraction and transportation processes. These pressure changes can cause significant damage to the infrastructure. Blast Joints are essential in preventing the destruction of pipelines and reducing the risk of hazardous spills and explosions. They are commonly installed in high-pressure gas pipelines, offshore rigs, and refinery systems to maintain system integrity.

The petrochemical industry requires the safe transport of chemicals, fuels, and gases through pipelines, often under high pressures. Blast Joints are critical in safeguarding the pipes against pressure fluctuations caused by chemical reactions or sudden temperature changes. By absorbing the shock from these surges, Blast Joints ensure that petrochemical facilities run smoothly and safely.

In power plants, especially those that use natural gas or coal, pipelines are constantly subjected to high pressures and temperature variations. Blast Joints are used in these systems to absorb the impact of pressure spikes, ensuring the stability of the entire energy production process. By maintaining the integrity of the piping, Blast Joints help prevent system failures that could lead to power outages or safety hazards.

Water treatment plants often rely on large piping systems to transport treated water through various stages of filtration. Blast Joints help mitigate the risk of damage from pressure surges or sudden shutdowns. They ensure that the water supply remains uninterrupted and that the piping system remains functional under varying pressure conditions.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD., we specialize in providing high-quality Blast Joints that enhance the performance, safety, and longevity of industrial piping systems. Our products are designed with advanced technology and robust materials to withstand the harshest operating conditions, offering reliable protection against pressure surges, explosions, and other stress-inducing factors.

With years of experience in manufacturing oil and gas equipment, we pride ourselves on delivering durable, efficient, and cost-effective solutions for our clients. Whether you are in the oil and gas industry, petrochemicals, or any other sector that relies on high-pressure piping systems, our Blast Joints are engineered to meet your specific needs.

If you’re looking to improve the safety and performance of your piping system, we invite you to get in touch with us to learn more about our range of Blast Joints and how they can help optimize your operations.

In summary, Blast Joints are indispensable components in industrial piping systems, providing essential protection against pressure surges, explosions, and other forces that can compromise pipeline integrity. By absorbing shock and maintaining system stability, Blast Joints enhance the safety, efficiency, and longevity of pipelines across various industries.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD., we are committed to delivering top-quality solutions for your industrial piping needs. If you're interested in exploring how our Blast Joints can improve your systems, we encourage you to contact us. Our team is here to assist you in ensuring the reliability and safety of your operations.