Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

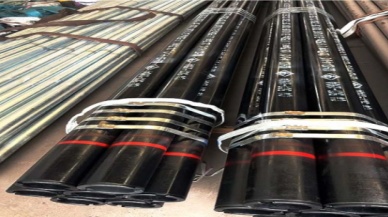

In high-pressure systems, whether they are used in industrial applications, oil and gas exploration, or chemical processing, safety is of paramount importance. These systems operate under extreme conditions where even a minor failure can have catastrophic consequences. One crucial component in these systems that contributes significantly to safety is the blast joint. This often-overlooked component plays a vital role in ensuring the integrity of the system under high-pressure and high-temperature conditions.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD, we specialize in providing reliable equipment and solutions for high-pressure systems, including the design and supply of blast joints that ensure safe operation.

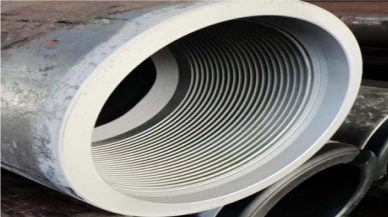

A blast joint is a critical safety component used in high-pressure systems to protect the piping and machinery from the immense forces generated by pressure surges, shocks, or explosions. These joints are typically made of durable materials designed to absorb and dissipate the energy from such events, preventing damage to the system and protecting personnel.

Blast joints are commonly used in industries like oil and gas, chemical processing, and power generation, where high-pressure systems are regularly exposed to fluctuations in pressure, temperature, and flow. The primary function of these joints is to prevent catastrophic failures by absorbing the sudden pressure spikes, ensuring the system remains intact and operational.

In high-pressure systems, such as those used in the oil and gas industry, chemical processing, and power generation, the safety and reliability of the system are crucial. One of the most essential components in these systems to ensure safe and efficient operation is the blast joint. Blast joints play a critical role in maintaining the integrity of the system, preventing damage from pressure surges, explosions, vibrations, and temperature fluctuations. Below, we explore the key functions of blast joints and how they contribute to the safe and reliable operation of high-pressure systems.

Pressure surges, also known as water hammer or pressure spikes, are one of the most common hazards in high-pressure systems. These surges typically occur due to sudden changes in the system, such as when valves close rapidly, pumps fail, or flow directions change abruptly. When pressure surges occur, they generate extreme forces that travel through the pipes, potentially causing ruptures, joint failures, or even catastrophic equipment damage.

Blast joints are specifically designed to protect the system from these surges. They act as shock absorbers, absorbing the rapid increases in pressure and dissipating the energy, which helps prevent the pressure spike from reaching critical components like pipes, joints, and valves. By doing so, blast joints significantly reduce the potential for damage caused by pressure fluctuations, enhancing the overall safety of the system. This function is especially important in high-pressure systems where the risk of pressure spikes is high and the consequences of system failure could be severe.

In certain high-risk environments, such as oil and gas facilities or chemical plants, explosions due to volatile gases or liquids under pressure can present significant risks. If an explosion occurs, it can generate a shockwave that can damage nearby equipment, rupture pipes, or cause secondary explosions. The consequences of such an event can be catastrophic, leading to operational downtime, loss of equipment, or even harm to personnel.

Blast joints play a critical role in explosion mitigation. These joints are specifically designed to absorb and redirect the pressure generated by an explosion, reducing its impact on the surrounding system. The blast joint dissipates the shockwave, preventing it from traveling along the pipes and reaching other parts of the system. This not only helps prevent further damage to the system but also minimizes the risk of secondary explosions that can be triggered by the shockwave.

High-pressure systems, particularly those with pumps, turbines, and compressors, are prone to significant vibration during operation. This vibration can arise from the continuous movement of fluids, machinery operation, and pressure fluctuations. If left unchecked, the vibrations can lead to fatigue damage, causing wear and tear on pipes, joints, and other critical components. Over time, this can result in leaks, ruptures, or even system failures, resulting in costly downtime and repairs.

Blast joints help mitigate these vibrations by providing a flexible connection between components. The flexibility of blast joints allows them to absorb and dampen the vibrations generated by the system, preventing them from traveling along the pipes and damaging other parts of the system. By reducing the transmission of vibrations, blast joints help maintain the integrity of the entire system.

High-pressure systems, particularly those used in oil and gas extraction or chemical processing, are subject to extreme temperature fluctuations. These fluctuations can lead to expansion and contraction of materials, which can result in stress on joints, pipes, and valves.

Blast joints are designed to accommodate these temperature changes. The materials used in blast joints are often chosen for their thermal resistance and ability to expand and contract without losing integrity. This helps prevent leaks, ruptures, or failures caused by temperature-induced stresses in the system.

High-pressure systems operate under conditions that can create significant stresses on the materials and components within the system. Without proper protection, these stresses could cause catastrophic failures, leading to costly downtime, damage to equipment, or even accidents involving personnel. Blast joints ensure that the system’s integrity is maintained by absorbing sudden pressure surges and reducing the risk of mechanical failures. This makes blast joints an essential part of any high-pressure system, helping to maintain safety and reliability.

In industries such as oil and gas, chemicals, and power generation, the risks associated with high-pressure systems go beyond equipment damage. A failure could potentially lead to explosions, leaks of hazardous materials, or fires, posing serious risks to human life and the environment. Blast joints are vital for human safety as they prevent the propagation of catastrophic failures, minimizing the impact of pressure spikes or explosions. By absorbing the shock from sudden pressure changes, blast joints protect operators, workers, and the surrounding environment from dangerous incidents.

Many industries that use high-pressure systems are subject to strict regulations regarding safety and operational standards. These regulations often require that safety devices, such as blast joints, be installed to ensure the safe operation of equipment. Failure to comply with these standards could result in legal penalties, shutdowns, or significant safety hazards. By incorporating blast joints into your high-pressure systems, you ensure that your operations meet industry regulations, safeguarding your business from potential legal and financial consequences.

Without blast joints, high-pressure systems are more susceptible to sudden failures and costly repairs. A pressure surge or explosion could damage the entire system, resulting in extended downtime for repairs and increased maintenance costs. Blast joints help minimize these risks by absorbing pressure fluctuations and protecting the system’s components from damage. As a result, the need for costly repairs and unplanned downtime is significantly reduced. This enhances the overall efficiency and profitability of the plant by ensuring continuous operation.

Selecting the right blast joint for your high-pressure system requires careful consideration of several factors, including the system’s pressure, temperature, material compatibility, and the type of materials being processed. A few key factors to consider include:

Pressure Rating: The blast joint should be rated to handle the maximum pressure expected in the system. It’s essential to choose a joint that can withstand pressure surges and ensure system integrity.

Material Compatibility: The materials used in the blast joint should be compatible with the materials in the high-pressure system, such as metals, alloys, or composite materials. This ensures that the joint can effectively handle thermal expansion, pressure, and vibrations without failure.

Temperature Resistance: Given the high temperature fluctuations in many high-pressure systems, selecting a blast joint with the right thermal resistance is essential to prevent material degradation or failure.

Flexibility: The blast joint must provide sufficient flexibility to accommodate the movement and vibrations within the system, especially if the system is subject to regular pressure changes or mechanical vibrations.

In high-pressure systems, blast joints are a critical safety component that ensures system integrity, protects against catastrophic failures, and maintains the safety of both personnel and the environment. They help mitigate the impact of pressure surges, explosions, and vibrations, all of which are common risks in industries like oil and gas, chemical processing, and power generation.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD, we are dedicated to providing high-quality blast joints and hydraulic equipment that enhance the safety, efficiency, and reliability of high-pressure systems. If you’re looking for durable, high-performance blast joints or need guidance on selecting the right equipment for your operations, we are here to help. Contact us today for more information on our products and solutions, and let us help ensure the safety and longevity of your high-pressure systems.