Views: 0 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

In industrial operations, particularly those involving pipelines, oil and gas, or other high-pressure systems, the integrity of various components is crucial for ensuring smooth and safe operations. One such critical component is the blast joint, which plays a vital role in the functionality of these systems. Despite their importance, many operators overlook the need for regular maintenance of blast joints, which can lead to significant operational issues, including system failure, costly downtime, and even safety hazards.

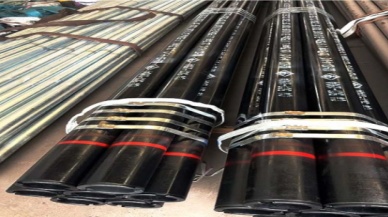

A blast joint is a type of specialized connection used in industrial piping systems, typically in the oil, gas, chemical, and power generation industries. These joints are designed to withstand high-pressure environments, such as those found in oil and gas pipelines, where rapid pressure changes or thermal expansion may occur. A blast joint is engineered to absorb shock loads, vibrations, and pressure surges, acting as a protective buffer for the piping system.

In essence, blast joints serve as safety mechanisms that prevent damage to the rest of the piping system during pressure fluctuations, making them an essential component for maintaining the integrity of the system as a whole.

The importance of regular maintenance for blast joints cannot be overstated. Just like any other integral part of an industrial system, blast joints endure constant wear and tear due to the extreme pressure, temperature fluctuations, and mechanical stresses they face during operation. Without regular upkeep, the functionality of these critical components can be compromised, leading to unexpected failures, costly downtime, and safety hazards. This makes routine maintenance a vital practice for preventing issues and ensuring the longevity of the entire system.

Here’s a deeper look at why maintaining blast joints regularly is essential for industrial operations:

The primary role of a blast joint is to act as a safety mechanism, preventing leaks and structural failures in high-pressure systems. These joints are designed to absorb shock loads, accommodate thermal expansion, and prevent catastrophic failures. However, over time, seals and gaskets within the joints can degrade due to the repeated stresses they endure. This degradation can lead to leaks, potentially resulting in hazardous situations like fluid or gas escapes.

Regular inspection and maintenance can help identify early signs of wear such as cracking, corrosion, or material degradation. This proactive approach allows maintenance teams to address these issues before they evolve into more significant problems that could damage the surrounding components, cause extensive leaks, or lead to system shutdowns. Early identification and repair of minor issues can significantly reduce the likelihood of catastrophic failures and the high costs associated with major repairs or replacements.

In industrial operations, downtime is expensive, not only in terms of lost productivity but also in delayed deliveries and missed deadlines. Blast joints, especially those in high-demand systems, are susceptible to failure due to wear and tear, and if left unchecked, their malfunction can cause considerable system downtime.

The consequences of an unexpected blast joint failure can be severe. Depending on the issue, repairs or replacements can take hours or even days to complete, during which time production halts. This leads to an interruption in the manufacturing process, negatively impacting schedules, costing companies money, and potentially damaging client relationships.

Industries that operate with high-pressure systems, such as the oil and gas, chemical, and energy sectors, are inherently risky. The materials handled in these systems are often volatile and can be dangerous to both workers and the surrounding environment. If a blast joint fails, it can result in catastrophic accidents such as explosions, toxic gas leaks, or even fires.

Regular maintenance is essential for ensuring that blast joints perform as expected, maintaining the safety of both the operators and the environment. By inspecting and maintaining blast joints, companies can ensure that they are functioning correctly and mitigating risks associated with pressure surges, vibration, or thermal expansion. Moreover, well-maintained blast joints contribute to a safer working environment, reducing the potential for workplace accidents, environmental contamination, and costly liability issues.

Efficient operations are the cornerstone of industrial success, and the condition of blast joints plays a significant role in maintaining system efficiency. When blast joints wear out or fail, they can cause increased friction, flow restrictions, or uneven pressure, all of which can negatively affect the performance of the entire system. These inefficiencies can result in higher energy consumption, more frequent downtime, and increased operational costs.

A well-maintained piping system can operate for decades, but neglecting maintenance can significantly shorten its lifespan. Blast joints, as integral parts of these systems, directly contribute to the overall durability and longevity of the entire network. If these joints are regularly inspected and maintained, they help to prevent additional stress on other components, which can prolong the life of the entire piping system.

Regular maintenance of blast joints requires a systematic approach that includes inspection, cleaning, testing, and replacement as necessary. Here are some key practices that can help maintain the integrity and efficiency of blast joints:

Regular inspections are the cornerstone of effective blast joint maintenance. Inspections should be conducted at regular intervals based on the operational environment and manufacturer recommendations. These inspections should include checking for the following:

Cracking or Fractures: Over time, the materials in the blast joint may crack due to constant pressure changes, vibration, or thermal expansion.

Corrosion or Rust: Especially in environments with high humidity or corrosive substances, corrosion can compromise the integrity of the blast joint.

Seal Degradation: The seals and gaskets within the joint are prone to wear. If they become brittle or misshapen, they may fail to provide the necessary sealing function.

Alignment Issues: Misalignment due to improper installation or wear can cause excessive strain on the joint, leading to premature failure.

By identifying potential problems early on, operators can schedule repairs or replacements before a failure occurs.

Blast joints often accumulate debris, grime, and other contaminants over time. This can interfere with their function and lead to increased wear. Regular cleaning of the joints and the surrounding system is essential to maintaining optimal performance. Cleaning should be done using appropriate methods and solvents that do not damage the materials.

Additionally, some blast joints may require lubrication to prevent friction between moving parts. Regular lubrication ensures smooth operation and prevents unnecessary wear and tear.

Pressure testing is an essential part of blast joint maintenance. By conducting pressure tests, operators can verify that the joint is capable of handling the intended pressures without leaking or failing. Testing should be done periodically, especially after any repair or replacement work, to confirm that the joint is operating within safe parameters.

Despite regular maintenance, certain components of a blast joint, such as seals, gaskets, and internal springs, will wear out over time. It’s essential to replace these components before they fail. Proactively replacing worn parts during maintenance inspections prevents unexpected system failures and minimizes downtime.

Proper training for maintenance personnel is critical to ensuring that blast joint maintenance is performed effectively. Employees should be trained on the specific procedures for inspecting, cleaning, lubricating, and testing blast joints. Additionally, thorough documentation of maintenance activities, including inspection reports and replacement logs, helps ensure that no maintenance task is overlooked and provides a record of the joint’s condition over time.

Neglecting the maintenance of blast joints can result in serious consequences for industrial operations:

Unexpected Failures: Without regular inspections and maintenance, blast joints are more likely to fail unexpectedly, causing costly downtime and repairs.

Safety Risks: A poorly maintained blast joint can lead to leaks, explosions, or system failures, creating hazardous conditions for workers and the environment.

Increased Costs: Delayed maintenance leads to higher repair costs and the need for more frequent replacements, ultimately increasing the overall cost of operation.

Reduced System Efficiency: Worn or damaged blast joints can hinder the efficiency of the entire system, resulting in higher energy consumption and operational costs.

Regular maintenance of blast joints is an essential practice for ensuring the smooth, safe, and efficient operation of industrial systems. By adhering to a routine maintenance schedule, companies can prevent leaks, minimize downtime, improve safety, and extend the lifespan of their equipment. Proactive care also leads to improved operational efficiency and reduced overall costs.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD., we understand the importance of reliable and high-quality blast joints in industrial applications. Our products are designed to meet the highest standards of performance and durability. If you’re looking for more information about our blast joint solutions or need expert advice on maintenance best practices, we invite you to contact us today. We are committed to providing the best solutions to support the longevity and performance of your industrial systems.