Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

In the world of manufacturing, precision and accuracy are paramount. Whether you're producing automotive parts, industrial equipment, or oil equipment, ensuring that every component meets stringent specifications is essential. One of the most critical aspects of maintaining product quality is lead gauging—a process that measures the alignment, positioning, and sizing of lead components to ensure they meet industry standards. This article explores the importance of accurate lead gauging in quality control, highlighting its role in manufacturing processes, the tools used, and the benefits it provides for product reliability and performance.

Lead gauging is the process of measuring the dimensions and alignment of lead components during the manufacturing process. The term "lead" refers to the angle of a part relative to its surrounding surfaces, and accurate gauging ensures that parts fit together correctly and meet the required performance criteria.

For example, in industries such as oil and gas equipment manufacturing, lead components may be used in valves, seals, and other essential parts. Lead gauging involves measuring the size, shape, and angle of these components to ensure they will function properly in their final application.

Accurate lead gauging is not just about measuring dimensions; it’s also about ensuring that the component will perform as expected under stress, pressure, and in various environmental conditions. It is an essential part of the quality control process because it helps manufacturers detect potential issues early and address them before the parts are integrated into final products.

In manufacturing, especially in industries where machinery or equipment must operate under extreme conditions, the smallest mistake can lead to catastrophic failures. Accurate lead gauging is one of the best ways to ensure that products meet rigorous industry standards. Poorly gauged leads can result in parts that do not fit together correctly, affecting the overall functionality of the product. For example, an improperly gauged lead in an oil valve can lead to leaks, malfunctions, or even equipment failure in critical applications.

Accurate gauging minimizes the chances of defects, reduces the number of rejected products, and enhances the consistency of product manufacturing. This is crucial not only for maintaining high-quality standards but also for reducing production costs associated with rework, waste, and warranty claims.

When lead components are measured accurately, the final product performs optimally. This is especially true for mechanical parts in high-stress environments, like those used in the oil and gas industry, where precision is necessary to withstand high pressures and temperatures. Lead gauging ensures that components are manufactured with precise tolerances, which directly impacts the product's efficiency, durability, and safety.

For example, in a valve assembly, accurate lead angles ensure that the parts seal properly and operate smoothly without causing wear and tear over time. Gauging the lead dimensions properly ensures a tight, reliable seal that can withstand pressure changes without fail. Accurate lead gauging can therefore improve the overall lifespan of products, reducing the likelihood of unexpected failures and costly repairs.

While it may seem like a cost-saving measure to skip precise gauging, the truth is that inaccurate lead measurements can result in significant waste in the form of defective parts, additional labor to fix issues, and production delays. By ensuring accurate lead gauging from the start, manufacturers can reduce the number of rejected products, minimize the risk of expensive recalls, and lower the costs associated with rework and repairs.

An accurate and consistent lead gauging process means fewer product defects, fewer material wastage, and fewer production delays, which can ultimately lead to a more streamlined production process. Moreover, the use of accurate lead gauging equipment helps improve the efficiency of the production line, enhancing throughput and reducing unnecessary costs.

Manufacturers are often required to meet stringent industry regulations and standards, especially in highly regulated industries like aerospace, oil and gas, and automotive manufacturing. Lead gauging is critical in meeting these standards, as many regulatory bodies require precise measurements for certain components to ensure that they meet safety and performance specifications.

For instance, in the oil and gas industry, components that don’t meet the required tolerances can jeopardize safety and lead to severe consequences. Accurate lead gauging helps ensure that products comply with both local and international standards, providing manufacturers with a reliable way to demonstrate their commitment to quality and safety.

In today's competitive market, customer satisfaction is paramount. Clients expect products that perform reliably and meet specific quality standards. By implementing accurate lead gauging as part of your quality control process, you ensure that your products meet customer expectations for performance and durability.

For businesses in industries such as oil and gas, where the stakes are high and the products are critical, ensuring that each component meets the required specifications is key to maintaining strong customer relationships. Delivering high-quality, well-gauged products not only helps in retaining existing customers but also in attracting new ones through positive recommendations and referrals.

To achieve accurate results in lead gauging, manufacturers use a variety of precision measurement tools. Some of the most commonly used tools include:

Micrometers and calipers are essential tools for measuring the dimensions of lead components with high precision. These tools can measure the outer diameter, inner diameter, and thickness of parts, ensuring they meet the necessary tolerances for lead.

Coordinate measuring machines (CMM) are advanced devices used to measure the exact physical geometries of a part. CMMs can detect even the smallest discrepancies in the lead dimensions and provide detailed reports on component accuracy. These machines are often used for parts that require extreme precision and are especially useful in industries like aerospace and oil and gas manufacturing.

Digital gauges and micrometers are used to provide highly accurate and repeatable measurements. These instruments can measure angles and dimensions down to the micron level, ensuring that the leads are within the precise tolerances required for quality control.

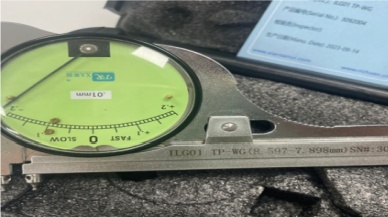

Lead angle gauges are designed specifically for measuring the angle of a component’s lead. These tools are crucial for ensuring that the angle aligns correctly with other parts, especially in assemblies that require perfect fits for sealing or mechanical performance.

Laser-based gauging systems provide non-contact measurement solutions, making them ideal for delicate components that cannot be touched or handled directly. These systems use laser technology to measure the dimensions and lead angles of components with high precision.

To integrate lead gauging effectively into your quality control process, it’s essential to establish standardized procedures and implement the right tools. Here are a few steps to ensure accuracy in lead gauging:

Ensure that all operators are following the same measurement protocols to maintain consistency across the production line. This includes using the same tools, adhering to specified tolerances, and taking measurements at designated stages in the manufacturing process.

Regularly calibrate your gauging tools to maintain accuracy. Tools such as micrometers and CMMs should be calibrated to industry standards to ensure that the measurements are reliable and precise.

Implement a system for continuously monitoring the accuracy of lead measurements throughout the production process. Regular training sessions for your quality control team will also help them stay up to date on the latest techniques and best practices for accurate lead gauging.

Consider using automated gauging systems that can detect deviations from the standard in real-time. These systems can help reduce human error and improve the overall efficiency of the lead gauging process.

Accurate lead gauging is an integral part of quality control that ensures your products meet the required specifications for performance, safety, and reliability. By implementing precise lead measurement processes, manufacturers can enhance product quality, improve performance, reduce costs, and maintain compliance with industry standards.

At TIANJIN RICHSEN OIL EQUIPMENT CO., LTD, we understand the critical role that accurate lead gauging plays in the manufacturing of high-quality oil equipment. Our commitment to precision and quality control ensures that every product we produce meets the highest standards of performance and safety. We recommend that manufacturers invest in the right gauging tools and processes to ensure the best outcomes for their products and customers.

If you're interested in learning more about how TIANJIN RICHSEN OIL EQUIPMENT CO., LTD can support your manufacturing needs with precision gauging tools and quality control solutions, feel free to get in touch with us. Our team is ready to help you optimize your production processes and ensure the reliability and durability of your products.