Views: 0 Author: Site Editor Publish Time: 2025-06-17 Origin: Site

In the demanding environment of oil and gas exploration, API 5CT casing couplings play a critical role in ensuring well integrity. These components are used to join sections of casing pipes, forming a continuous and pressure-resistant conduit in the wellbore. Casing provides structural support to the well and isolates different underground zones to prevent fluid migration.

A casing coupling, although a relatively small component, is essential to the reliability of the entire casing string. If the coupling fails—whether due to inadequate strength, poor threading, or incompatibility with casing material—the consequences can be severe, including leaks, structural collapse, or well control issues.

Selecting the right API 5CT casing coupling is especially important in challenging well environments, such as high-pressure, high-temperature (HPHT) formations, deviated or horizontal wells, and corrosive geological zones. The wrong choice can compromise well integrity and result in costly failures or safety hazards.

The American Petroleum Institute (API) has established comprehensive standards to ensure the safety, quality, and consistency of oilfield tubular goods. Two of the most critical standards related to casing couplings are API 5CT and API 5B.

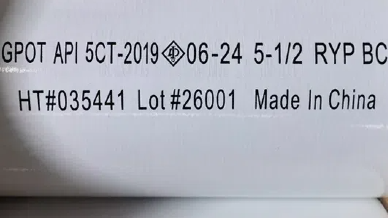

API 5CT governs the design, materials, performance properties, and testing of casing and tubing used in oil and gas wells. It specifies the mechanical and chemical requirements for the steel used, including grades, dimensions, and testing protocols. API 5B, on the other hand, focuses on the threading, gauging, inspection, and thread lubricant requirements to ensure a reliable and secure connection between casing strings.

Choosing couplings manufactured in strict accordance with these standards offers several important benefits:

Interchangeability: API standardization allows components from different manufacturers to be used together without compatibility issues.

Dimensional and Mechanical Consistency: Operators can expect uniform wall thickness, OD, thread form, and tensile properties.

Verified Reliability: Each coupling is subjected to rigorous inspection, including nondestructive testing, thread gauging, and heat treatment verification, ensuring reliable performance in demanding conditions.

By using certified API 5CT and 5B couplings, operators significantly reduce the risks of connection failure, leaks, or misalignment during drilling and production.

API 5CT casing couplings are produced in a range of outer diameters from 4-1/2 inches to 20 inches, aligning with standard casing pipe sizes used in surface, intermediate, and production casing applications. Proper size matching is crucial to ensure seamless connection and load-bearing capacity across the wellbore.

Beyond size, material grade compatibility plays a vital role. Couplings must be manufactured from materials that match or exceed the mechanical strength and environmental resistance of the casing pipes they connect. Some of the most common API grades include:

J55 and K55: Entry-level grades used in shallow wells or surface casing with low-pressure and minimal corrosive exposure.

N80-1 and N80-Q: Intermediate strength options ideal for deeper wells, offering better performance in slightly harsher conditions.

L80: Known for its increased resistance to CO₂ corrosion; suitable for mildly sour service environments.

P110 and Q125: High-strength grades used in deep or high-pressure/high-temperature (HPHT) wells where extreme stress is expected.

C90, T95, and C110: These grades are specially designed for sour gas environments, offering robust sulfide stress corrosion cracking (SSCC) resistance.

To maintain the overall strength and integrity of the casing string, the selected coupling must be of equal or higher grade than the casing pipe. Mismatched grades can become a weak point under axial, tensile, or compressive loads, increasing the risk of failure during drilling or production operations.

Threading is a critical aspect of API 5CT casing couplings, as it directly influences sealing reliability, mechanical strength, and ease of makeup during installation. The connection type determines how effectively the casing string resists internal pressure, axial loads, and environmental stress over the life of the well. API recognizes three standard thread types for casing couplings:

STC (Short Thread Coupling):

STC is an economical option with a relatively short thread engagement length. It is easy to manufacture and assemble, making it suitable for shallow and low-pressure wells where the demands on the connection are moderate.

LTC (Long Thread Coupling):

LTC features longer thread engagement than STC, resulting in better tensile strength and improved sealing under moderate pressure. It is commonly used in medium-depth wells where higher mechanical integrity is required.

BTC (Buttress Thread Coupling):

BTC is the most widely used type in the oilfield. Its robust buttress thread profile offers excellent resistance to axial and tensile loads. Designed for high-load applications, BTC is the preferred choice for deeper wells and standard high-pressure environments.

For more demanding drilling environments—such as extended-reach drilling, highly deviated wells, and HPHT (high-pressure, high-temperature) operations—standard API threads may not offer sufficient sealing performance or structural integrity. In these cases, operators often turn to premium thread designs that provide superior functionality:

TTGM-4 (VAM TOP Interchangeable): Engineered for leak-proof performance under severe conditions, TTGM-4 threads offer enhanced metal-to-metal sealing and torque strength.

New VAM and Big Omega: These connections are designed for high-tension and compression resistance, making them suitable for challenging offshore or ultra-deep onshore wells.

TSH PH6: Recognized for its exceptional fatigue resistance and flexibility in harsh environments, including gas-tight applications.

Premium threads often come certified with CAL IV test reports, verifying their performance under simulated well conditions, including extreme loads, high-pressure gas sealing, and thermal cycling.

In summary, the correct selection between standard and premium thread types should be based on well depth, pressure, temperature, and required mechanical strength. Choosing the appropriate thread connection enhances the overall safety and durability of the well.

The material used for API 5CT casing couplings must be consistent with the pipe to avoid weak points in the casing string. API standards require that couplings:

Be seamless

Match the grade, type, and PSL (Product Specification Level) of the casing

Undergo the same heat treatment (e.g., quenching and tempering)

Additionally, the manufacturing process must adhere to strict quality guidelines. Couplings should be produced from:

Coupling stock

Coupling blanks

Hot forgings (with exceptions for some grades)

Importantly, C110 and Q125 couplings must not be made from hot forgings due to their unique metallurgical requirements.

Consistency in wall thickness, thread accuracy, hardness, and concentricity are also key indicators of coupling quality. These ensure the coupling performs reliably over the well’s lifespan.

Wells are drilled in a wide range of environments, and the selection of casing couplings must account for specific operational conditions, such as:

Wells that contain CO₂, H₂S, or other corrosive gases require high-alloy or corrosion-resistant grades (e.g., L80 13Cr, C90, T95) to avoid sulfide stress cracking (SSC) or general corrosion failure.

Deeper wells face extreme temperature and pressure conditions. Grades like P110, Q125, and C110 are suited for these situations due to their high yield strength and heat-treated durability.

Casing couplings must withstand:

Tensile loads from pipe weight

Compressive forces during installation

Axial loads from directional drilling or formation movement

Proper material selection and premium threading improve performance under these stresses, reducing the risk of thread galling, coupling slippage, or failure during tripping.

Selecting the right API 5CT casing coupling is essential for ensuring well integrity, safety, and long-term operational efficiency. From standard API threads to premium, corrosion-resistant options for HPHT wells, each choice should be based on strict adherence to API 5CT/5B standards, proper size and grade matching, sealing performance, and environmental demands. To reduce operational risks and enhance well performance, partnering with a trusted supplier is crucial.

TIANJIN RICHSEN OIL EQUIPMENT CO., LTD offers a full range of high-quality API 5CT casing couplings, backed by professional expertise and strict quality control. For tailored solutions and reliable support, we invite you to learn more or contact RICHSEN directly for your project needs.